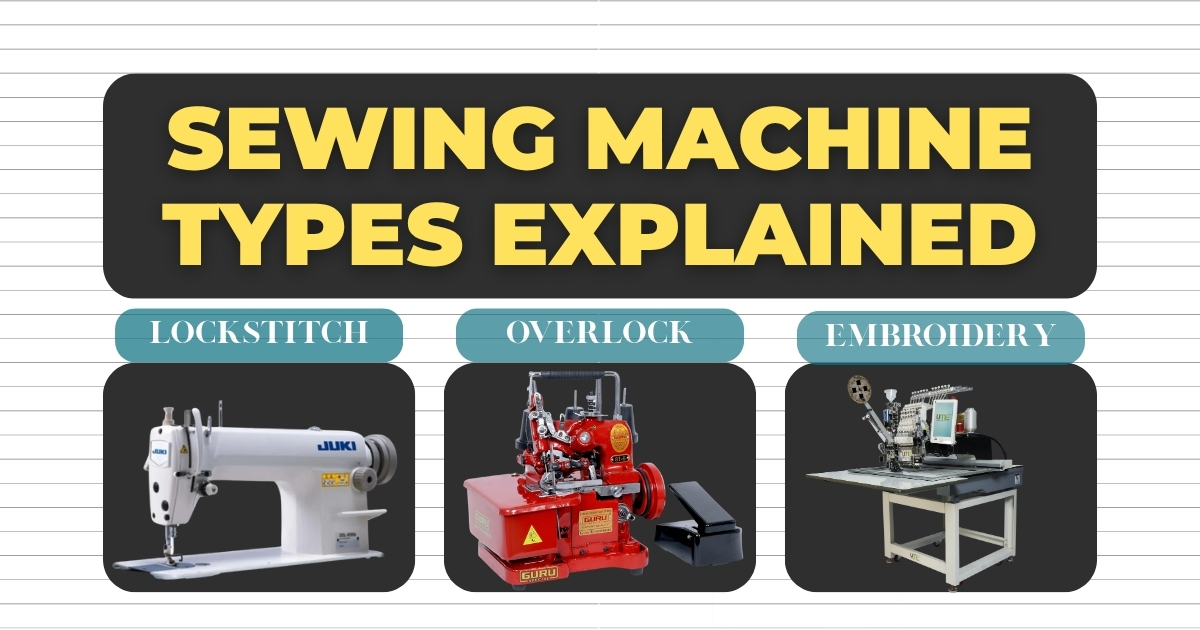

Sewing Machine Types Explained: Lockstitch, Overlock, and More

Choosing the right sewing machine means understanding the different types available and how each one serves your needs. From sturdy lockstitch units used in most domestic and commercial sewing to specialized overlock machines designed for finishing, here’s a complete guide explaining the main types of sewing machines, their uses, and what makes each one unique.

1. Lockstitch Machine

The lockstitch machine is the most common type of sewing machine. It uses two threads-one from the needle and one from the bobbin-to create strong, secure stitches that lock into the fabric. This mechanic makes lockstitch ideal for everyday sewing, garment construction, and basic alterations.

Key Features

- Produces straight, zigzag, and decorative stitches

- Suitable for light to medium fabrics

- Available in both domestic and heavy-duty industrial models

- Can be enhanced with automation like automatic thread trimming and knee lift

Common Uses

- Garments like shirts, pants, kurta sets

- Home décor items like pillowcases, curtains

- Light upholstery and quilting

2. Overlock (Serger) Machine

An overlock machine, or serger, trims edges and binds them in one swift movement. It uses multiple threads (typically 3–5) to finish seams neatly and prevent fraying. Industrial versions are standard in factories, while compact models suit home sewing.

Key Features

- Trims fabric edge, sews seam, and encases raw edges

- Produces professional overcast and rolled hems

- Fast and excellent for stretch fabrics

- Requires separate machine; cannot replace a lockstitch for main seams

Common Uses

- Finish seams in knitwear for strength and stretch

- Home décor edging and protective seam finishing

- Professional-quality edging for boutique garments

3. Coverstitch Machine

A coverstitch machine is used along hems and twin-needle stitching. It creates a clean, strong finish with multiple rows of parallel stitches on the top and a looper thread beneath, ideal for stretchy materials.

Key Features

- Double or triple row stitches visible from the top

- Strong cover stitch on the bottom for elasticity

- Great for hems on T-shirts, activewear, and knit fabric

- Often sold as a companion to overlock machines

Common Uses

- Survey seam finishes on stretch garments

- Reinforced hems and topstitching detail

- Neckline, sleeve, and bottom hems in jersey wear

4. Buttonhole and Button Sewing Machine

These specialized machines are designed for neat buttonholes and perfectly centered buttons-key for dress shirts and uniforms.

Key Features

- Creates buttonholes in one automatic pass

- Button sewing machines stitch buttons securely

- Can match uniform quality and precision

- Great for tailors and uniform stitching services

Common Uses

- School and corporate uniforms

- Formal wear requiring clean, uniform buttonholes

- Repair services for worn or missing buttons

5. Quilting & Embroidery Machines

Embroidery machines can add decorative stitches or detailed motifs, while quilting machines simplify large projects.

Key Features

- Embroidery: multi-needle heads, built-in patterns

- Quilting: wider throat space for quilts, long arms for comfort

- Available in sheerly computerized home versions

- Industrial units for professional quilt production

Common Uses

- Embroidered logos, motifs, and monograms

- Quilt piecing, large home décor stretches

- Custom decorative embellishments on apparel

6. Industrial Flatbed & Cylinder Machines

Industrial machines are built for bulk production and depend on machine type:

- Flatbed machines: Great for flat length fabrics, casual wear, quilts

- Cylinder arm machines: Perfect for tubular or small goods like sleeves, bags

Key Features

- Heavy-duty motors for continuous stitching

- Built for thick fabrics, leather, or multiple layers

- Belt or direct-drive motors for speed and efficiency

Common Uses

- Garment factories

- Shoe and accessory manufacturing

- Heavy-duty products like furniture upholstery and bags

7. Specialty Sewing Machines

A variety of specialized machines serve precise needs:

- Quilt binding machines (bias tape application)

- Blind stitch machines for invisible hems

- Topstitching machines with spring feed for thick layers

- Industrial post-bed or free-arm machines for cylindrical items

Common Uses

- Professional tailoring and garment finishing

- Custom stitching and smaller product lines

- High-end garment detailing

Comparative Table of Sewing Machine Types

| Machine Type | Starts At Price | Best Features | Common Use Cases |

|---|---|---|---|

| Lockstitch | ₹15,000 | Versatile, strong seams | General sewing and everyday garments |

| Overlock (Serger) | ₹20,000 | Professional finish, stretch seams | Knitwear, securing raw edges |

| Coverstitch | ₹25,000+ | Elastic, durable hems | T-shirts, baby clothing, activewear |

| Embroidery/Quilting | ₹30,000+ | Decorative stitching, large work | Logos, quilting, customized garments |

| Industrial Flatbed | ₹35,000+ | Loud, fast, continuous performance | Bulk garment and upholstery production |

| Cylinder/Free-Arm | ₹40,000+ | Sew sleeves, caps, bags easily | Petite items, cylindrical products |

How to Choose the Right Machine

- Define Your Needs

Think about your garments or products-do you need only stitching or will finishing and decoration matter? - Assess Fabric Types

Light cotton vs. denim and knit garments need different stitching quality and strength. - Check Workspace and Budget

Industrial machines require more space and investment; home units are compact but limited in function. - Consider Future Growth

If you plan to scale, choose a machine that accommodates a wider variety of garments or multiple processes.

Frequently Asked Questions (FAQs)

Can one machine do all types?

No—certain stitches require specialized machines. A full-service setup often includes a lockstitch unit, overlock, and perhaps an embroidery or quilting machine.

Is overlocking necessary for all garments?

Not always, but overlocking strengthens seams on stretchy or delicate fabrics and gives a clean, professional finish.

Which machine should I start with?

Start with a lockstitch machine-it forms the basis of most sewing, while other machines can be added later.

Are industrial machines suitable for home use?

They can be, but require more space, power, and noise tolerance. Consider whether their features match your home workspace need.

What’s the most cost-effective setup for home businesses?

A lockstitch machine paired with an overlock unit provides both basic stitching and professional edge finishes, without requiring industrial-level investment or space.

Final Thoughts

Understanding the types of sewing machines available helps you make smarter choices that fit your goals. Whether you’re starting with everyday sewing at home or planning to launch a boutique or production line, matching machine type with purpose ensures your success.

Start with essential stitching; expand thoughtfully into finishers, embroidery, or industrial-strength machines only when your business needs it. A well-chosen setup means smoother operations, higher quality products, and a clear growth path.