Servo Motor

Product Search

Showing all 6 results

The Sewing Machine Servo Motor: A Revolution in Sewing Industry

What is Sewing Machine Servo Motor?

What are the Types of Sewing Machine Servo Motor?

Brushless Servo Motor

Brushed Servo Motor

Compact Servo Motor

High-Torque Servo Motor

Low-Speed Servo Motor

Multi-Speed Servo Motor

Smart Servo Motor

Retrofit Servo Motor

Programmable Servo Motor

What are the benefits of a servo motor for a sewing machine?

Do you know why stitchers prefer this? The servo motors only use power when you’re actively sewing; isn’t that pretty interesting and beneficial? It not only saves energy but also reduces your electricity bill.

And are you bothered by the noisy whirring of a sewing machine motor? Then it’s time for you to switch to servo motors since they are quiet with a humming sound, and who doesn’t love a peaceful sewing process?

If you are tired of not having control over a sewing machine, then the servo motors are here to rescue you; with servo motors, you have control over your sewing machine with a smooth start, speed, and gradual stopping of the device.

Here is a quick note to go through the benefits of the servo motors:

Precise speed control

Energy efficiency

Quiet operation

Smooth start and stop

Better speed consistency

Longer motor life and fewer repair costs

Wide range of speeds

It is ideal for heavy fabrics for a variety of sewing projects

Environmentally friendly and overall energy consumption

User-friendly for sewers of all skill levels, from beginners to experienced professionals

Upgrade compatibility without having to purchase a new device.

How does a Sewing Machine Servo Motor Work?

Here is a quick guide on how a servo motor works, which gives you a long service life with easy maintenance.

The operator presses the foot pedal to start the sewing machine.

This sends a signal to the servo motor controller.

The controller then sends a signal to the servo motor, telling it to start rotating.

The servo motor rotates the shaft, which in turn drives the needle and feeds dog of the sewing machine.

The position sensor monitors the position of the rotor and sends this information back to the controller.

The controller compares the actual position of the rotor to the desired position and then sends a signal to the motor to correct any errors.

This process continues until the operator releases the foot pedal, at which point the servo motor stops rotating.

Where to buy a Sewing machine Servo Motor in Chennai?

Frequently Asked Questions

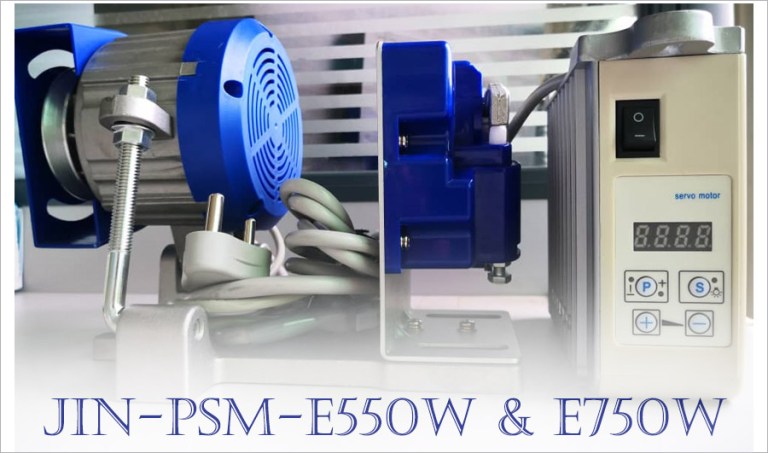

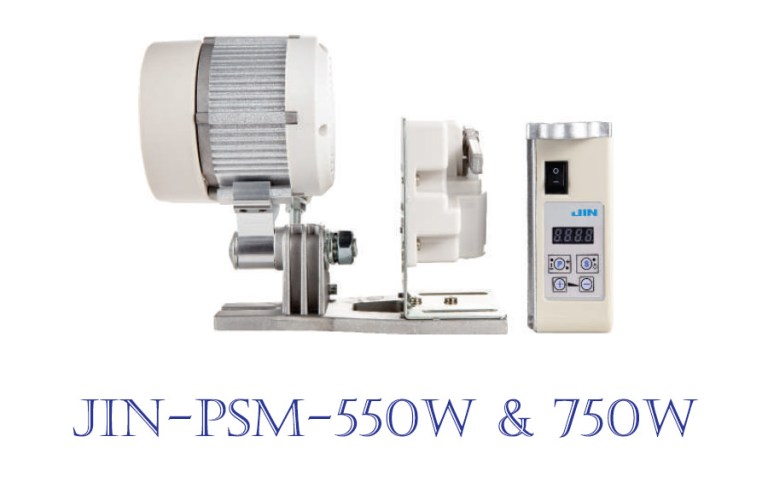

Sewing machine servo motors come in a variety of wattages, ranging from around 200 watts to 1000 watts or more.

Can I retrofit my old sewing machine with a servo motor?

It is possible to retrofit an old sewing machine with a servo motor.

Are sewing machine servo motors suitable for industrial sewing machines?

Yes, sewing machine servo motors are suitable for industrial sewing machines.

Are servo motors more energy-efficient than clutch motors?

Yes, servo motors are more energy-efficient than clutch motors.

What is the motor capacity of the Juki sewing machine?

Juki sewing machines come with a variety of motors, depending on the specific model.